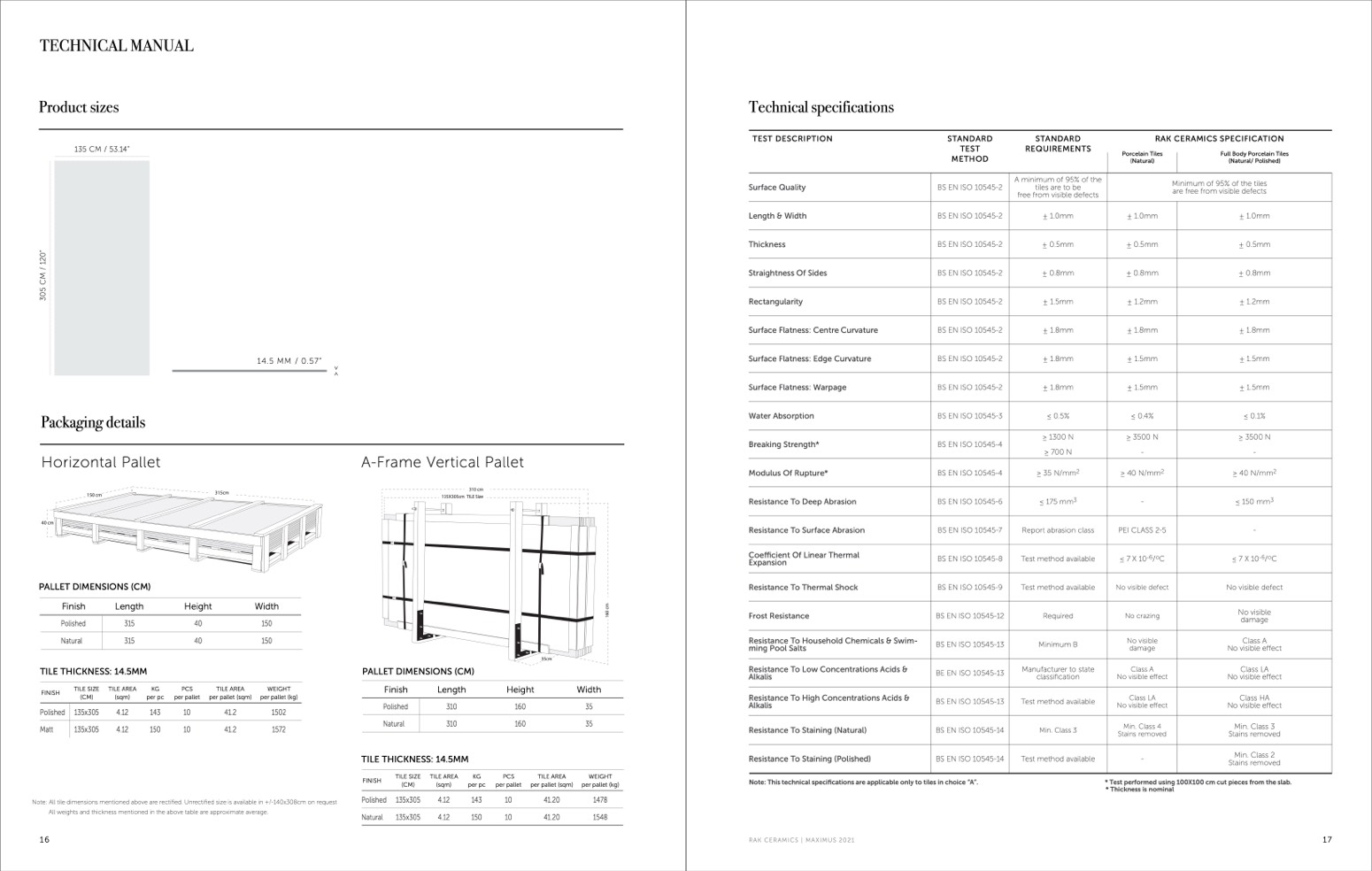

TECHNICAL MANUAL

Product sizes

135 CM / 53.14”

14.5 MM / 0.57”

Packaging details

Horizontal Pallet

150 cm

40 cm

PALLET DIMENSIONS (CM)

A-Frame Vertical Pallet

315cm

310 cm

135X305cm TILE Size

Finish

Polished

Natural

Length

315

315

Height

40

40

PCS

per pallet

10

10

Width

150

150

WEIGHT

per pallet (kg)

1502

1572

35cm

TILE THICKNESS: 14.5MM

PALLET DIMENSIONS (CM)

FINISH

TILE SIZE

(CM)

TILE AREA

(sqm)

4.12

4.12

KG

per pc

143

150

TILE AREA

per pallet (sqm)

41.2

41.2

Finish

Polished

Natural

Length

310

310

Height

160

160

PCS

per pallet

10

10

Width

35

35

WEIGHT

per pallet (kg)

1478

1548

Polished 135x305

Matt

135x305

TILE THICKNESS: 14.5MM

Note: All tile dimensions mentioned above are rectified. Unrectified size is available in +/-140x308cm on request

All weights and thickness mentioned in the above table are approximate average.

FINISH

Polished

Natural

TILE SIZE

(CM)

135x305

135x305

TILE AREA

(sqm)

4.12

4.12

KG

per pc

143

150

TILE AREA

per pallet (sqm)

41.20

41.20

16

Technical specifications

TEST DESCRIPTION

Surface Quality

Length & Width

Thickness

Straightness Of Sides

Rectangularity

Surface Flatness: Centre Curvature

Surface Flatness: Edge Curvature

Surface Flatness: Warpage

Water Absorption

Breaking Strength*

Modulus Of Rupture*

Resistance To Deep Abrasion

Resistance To Surface Abrasion

Coefficient Of Linear Thermal

Expansion

Resistance To Thermal Shock

Frost Resistance

Resistance To Household Chemicals & Swim-

ming Pool Salts

Resistance To Low Concentrations Acids &

Alkalis

Resistance To High Concentrations Acids &

Alkalis

Resistance To Staining (Natural)

Resistance To Staining (Polished)

STANDARD

TEST

METHOD

STANDARD

REQUIREMENTS

RAK CERAMICS SPECIFICATION

Porcelain Tiles

(Natural)

Full Body Porcelain Tiles

(Natural/ Polished)

BS EN ISO 10545-2

A minimum of 95% of the

tiles are to be

free from visible defects

Minimum of 95% of the tiles

are free from visible defects

BS EN ISO 10545-2

± 1.0mm

± 1.0mm

± 1.0mm

BS EN ISO 10545-2

± 0.5mm

± 0.5mm

± 0.5mm

BS EN ISO 10545-2

± 0.8mm

± 0.8mm

± 0.8mm

BS EN ISO 10545-2

± 1.5mm

± 1.2mm

± 1.2mm

BS EN ISO 10545-2

± 1.8mm

± 1.8mm

± 1.8mm

BS EN ISO 10545-2

± 1.8mm

± 1.5mm

± 1.5mm

BS EN ISO 10545-2

± 1.8mm

± 1.5mm

± 1.5mm

BS EN ISO 10545-3

≤ 0.5%

≤ 0.4%

≤ 0.1%

BS EN ISO 10545-4

≥ 1300 N

≥ 700 N

≥ 3500 N

-

≥ 3500 N

-

BS EN ISO 10545-4

≥ 35 N/mm2

≥ 40 N/mm2

≥ 40 N/mm2

BS EN ISO 10545-6

≤ 175 mm3

-

≤ 150 mm3

BS EN ISO 10545-7

Report abrasion class

PEI CLASS 2-5

-

BS EN ISO 10545-8

Test method available

≤ 7 X 10-6/oC

≤ 7 X 10-6/oC

BS EN ISO 10545-9

Test method available

No visible defect

No visible defect

BS EN ISO 10545-12

Required

No crazing

No visible

damage

BS EN ISO 10545-13

Minimum B

No visible

damage

Class A

No visible effect

BE EN ISO 10545-13

Manufacturer to state

classification

Class A

No visible effect

Class LA

No visible effect

BS EN ISO 10545-13

Test method available

Class LA

No visible effect

Class HA

No visible effect

BS EN ISO 10545-14

Min. Class 3

Min. Class 4

Stains removed

Min. Class 3

Stains removed

BS EN ISO 10545-14

Test method available

-

Min. Class 2

Stains removed

Note: This technical specifications are applicable only to tiles in choice “A”.

* Test performed using 100X100 cm cut pieces from the slab.

* Thickness is nominal

RAK CERAMICS | MAXIMUS 2021

17

1

6

0

c

m

>

<

3

0

5

C

M

/

1

2

0

”