Storytelling

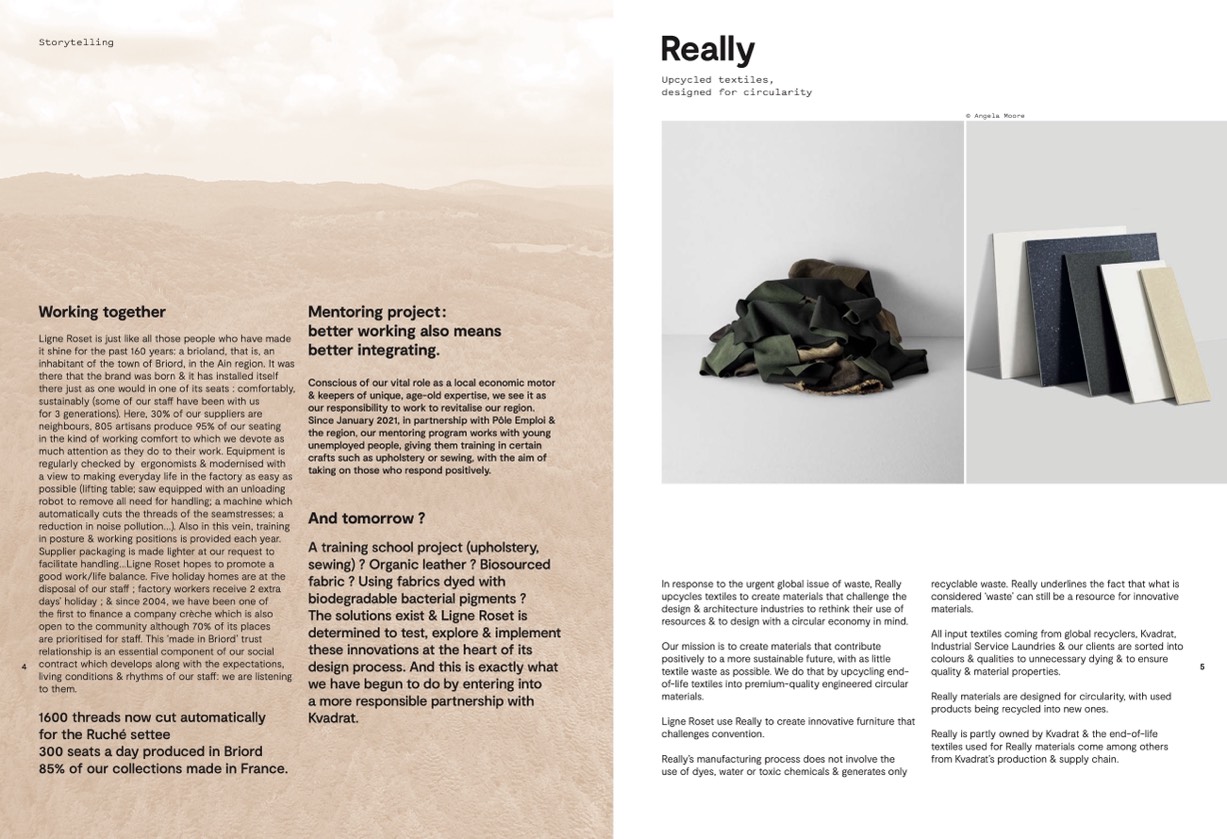

Really

Upcycled textiles,

designed for circularity

© Angela Moore

Working together

Ligne Roset is just like all those people who have made

it shine for the past 160 years: a brioland, that is, an

inhabitant of the town of Briord, in the Ain region. It was

there that the brand was born & it has installed itself

there just as one would in one of its seats : comfortably,

sustainably (some of our staff have been with us

for 3 generations). Here, 30% of our suppliers are

neighbours, 805 artisans produce 95% of our seating

in the kind of working comfort to which we devote as

much attention as they do to their work. Equipment is

regularly checked by ergonomists & modernised with

a view to making everyday life in the factory as easy as

possible (lifting table; saw equipped with an unloading

robot to remove all need for handling; a machine which

automatically cuts the threads of the seamstresses; a

reduction in noise pollution...). Also in this vein, training

in posture & working positions is provided each year.

Supplier packaging is made lighter at our request to

facilitate handling...Ligne Roset hopes to promote a

good work/life balance. Five holiday homes are at the

disposal of our staff ; factory workers receive 2 extra

days’ holiday ; & since 2004, we have been one of

the first to finance a company crèche which is also

open to the community although 70% of its places

are prioritised for staff. This ‘made in Briord’ trust

relationship is an essential component of our social

4 contract which develops along with the expectations,

living conditions & rhythms of our staff: we are listening

to them.

1600 threads now cut automatically

for the Ruché settee

300 seats a day produced in Briord

85% of our collections made in France.

Mentoring project :

better working also means

better integrating.

Conscious of our vital role as a local economic motor

& keepers of unique, age-old expertise, we see it as

our responsibility to work to revitalise our region.

Since January 2021, in partnership with Pôle Emploi &

the region, our mentoring program works with young

unemployed people, giving them training in certain

crafts such as upholstery or sewing, with the aim of

taking on those who respond positively.

And tomorrow ?

A training school project (upholstery,

sewing) ? Organic leather ? Biosourced

fabric ? Using fabrics dyed with

biodegradable bacterial pigments ?

The solutions exist & Ligne Roset is

determined to test, explore & implement

these innovations at the heart of its

design process. And this is exactly what

we have begun to do by entering into

a more responsible partnership with

Kvadrat.

In response to the urgent global issue of waste, Really

upcycles textiles to create materials that challenge the

design & architecture industries to rethink their use of

resources & to design with a circular economy in mind.

Our mission is to create materials that contribute

positively to a more sustainable future, with as little

textile waste as possible. We do that by upcycling end-

of-life textiles into premium-quality engineered circular

materials.

Ligne Roset use Really to create innovative furniture that

challenges convention.

Really’s manufacturing process does not involve the

use of dyes, water or toxic chemicals & generates only

recyclable waste. Really underlines the fact that what is

considered ‘waste’ can still be a resource for innovative

materials.

All input textiles coming from global recyclers, Kvadrat,

Industrial Service Laundries & our clients are sorted into

colours & qualities to unnecessary dying & to ensure

quality & material properties.

5

Really materials are designed for circularity, with used

products being recycled into new ones.

Really is partly owned by Kvadrat & the end-of-life

textiles used for Really materials come among others

from Kvadrat’s production & supply chain.