GENERAL INFORMATION

Malleable cast iron pipe fittings – UNI eN 10242 rule

PRODUCT

the characteristic of malleable cast iron fittings used for water, gas

and other installations are in accordance with ISO-49 International rule

and eN 10242 European rules.

MECHANICAL PROPERTIES

Materials used are in accordance with eN 1562 rule as regards me-

chanical properties.

MATERIAL

the material used is malleable cast iron in accordance with eN 1562

rule.

cast iron available is :

• eN-GJMW-4005 (white heart malleable cast iron class a).

• eN-GJMB-350-10 (black heart malleable cast iron class a).

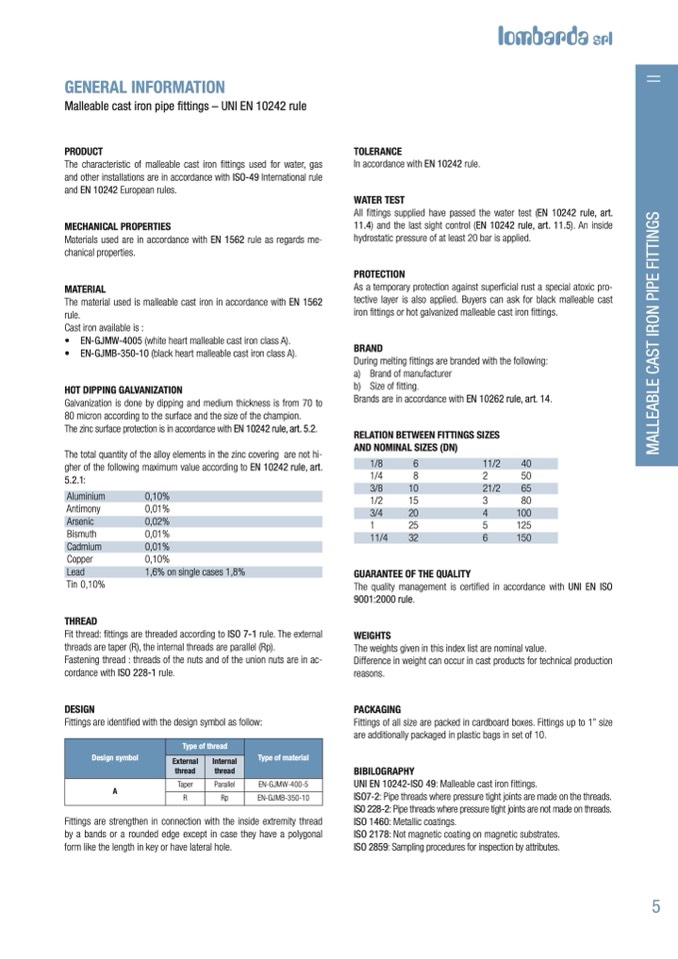

HOT DIPPING GALVANIZATION

galvanization is done by dipping and medium thickness is from 70 to

80 micron according to the surface and the size of the champion.

the zinc surface protection is in accordance with eN 10242 rule, art. 5.2.

the total quantity of the alloy elements in the zinc covering are not hi-

gher of the following maximum value according to eN 10242 rule, art.

5.2.1:

TOLERANCE

In accordance with eN 10242 rule.

WATER TEST

all fittings supplied have passed the water test (eN 10242 rule, art.

11.4) and the last sight control (eN 10242 rule, art. 11.5). an inside

hydrostatic pressure of at least 20 bar is applied.

PROTECTION

as a temporary protection against superficial rust a special atoxic pro-

tective layer is also applied. Buyers can ask for black malleable cast

iron fittings or hot galvanized malleable cast iron fittings.

BRAND

During melting fittings are branded with the following:

a) Brand of manufacturer

b) Size of fitting.

Brands are in accordance with eN 10262 rule, art. 14.

RELATION BETWEEN FITTINGS SIZES

AND NOMINAL SIZES (DN)

lombarda

srl

aluminium

antimony

arsenic

Bismuth

cadmium

copper

lead

tin 0,10%

THREAD

Fit thread: fittings are

threads are taper (R), the internal threads are parallel (Rp).

Fastening thread : threads of the nuts and of the union nuts are in ac-

cordance with ISO 228-1 rule.

DESIGN

Fittings are identified with the design symbol as follow:

Fittings are strengthen in connection with the inside extremity thread

by a bands or a rounded edge except in case they have a polygonal

form like the length in key or have lateral hole.

1/8

6

1/4

8

3/8

10

1/

2

15

3/4

20

1

25

11/4

32

GUARANTEE OF THE QUALITY

11/2

40

2

50

21/2

65

3

80

4

100

5

125

6

150

0,10%

0,01%

0,02%

0,01%

0,01%

0,10%

1,6% on single cases 1,8%

threaded according to ISO 7-1 rule. the external

the quality management is certified in accordance with UNI eN ISO

9001:2000 rule.

WEIGHTS

the weights given in this index list are nominal value.

Difference in weight can occur in cast products for technical production

reasons.

PACKAGING

Fittings of all size are packed in cardboard boxes. Fittings up to 1” size

are additionally packaged in plastic bags in set of 10.

BIBILOGRAPHY

UNI eN 10242-ISO 49: Malleable cast iron fittings.

ISO7-2: Pipe threads where pressure tight joints are made on the threads.

IS0 228-2: Pipe threads where pressure tight joints are not made on threads.

ISO 1460: Metallic coatings.

ISO 2178: Not magnetic coating on magnetic substrates.

ISO 2859: Sampling procedures for inspection by attributes.

Design symbol

Type of thread

Type of material

External

thread

Internal

thread

A

taper

Parallel

EN-gJMW-400-5

R

Rp

EN-gJMB-350-10

5

M

a

l

l

e

a

B

l

e

c

a

S

t

I

R

O

N

p

I

p

e

f

I

t

t

I

N

G

S