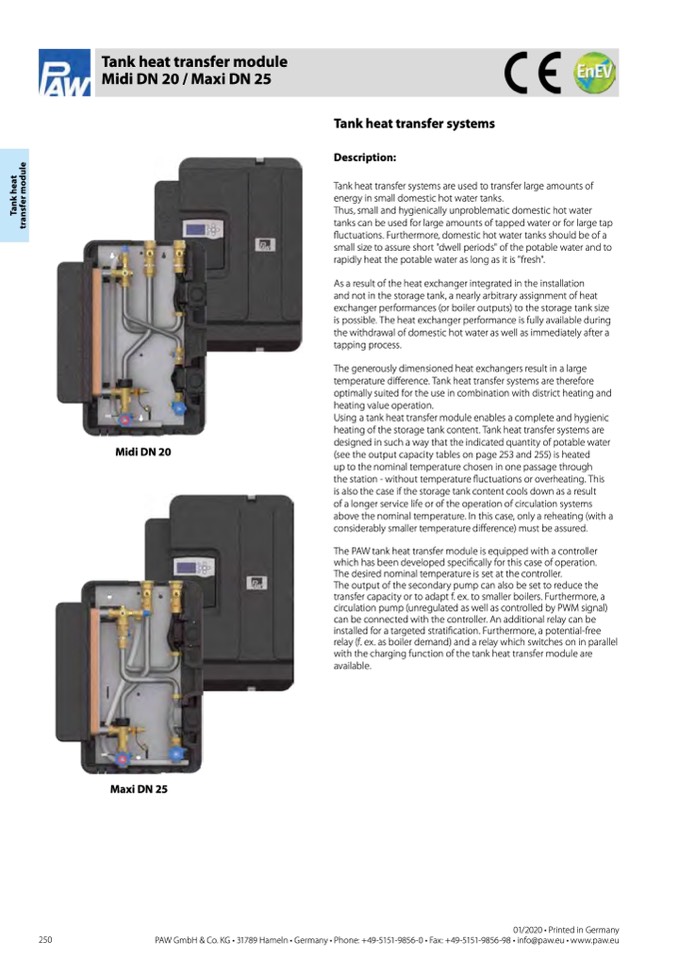

Tank heat transfer module

Midi DN 20 / Maxi DN 25

Midi DN 20

Tank heat transfer systems

Description:

Tank heat transfer systems are used to transfer large amounts of

energy in small domestic hot water tanks.

Thus, small and hygienically unproblematic domestic hot water

tanks can be used for large amounts of tapped water or for large tap

fluctuations. Furthermore, domestic hot water tanks should be of a

small size to assure short "dwell periods" of the potable water and to

rapidly heat the potable water as long as it is "fresh".

As a result of the heat exchanger integrated in the installation

and not in the storage tank, a nearly arbitrary assignment of heat

exchanger performances (or boiler outputs) to the storage tank size

is possible. The heat exchanger performance is fully available during

the withdrawal of domestic hot water as well as immediately after a

tapping process.

The generously dimensioned heat exchangers result in a large

temperature difference. Tank heat transfer systems are therefore

optimally suited for the use in combination with district heating and

heating value operation.

Using a tank heat transfer module enables a complete and hygienic

heating of the storage tank content. Tank heat transfer systems are

designed in such a way that the indicated quantity of potable water

(see the output capacity tables on page 253 and 255) is heated

up to the nominal temperature chosen in one passage through

the station - without temperature fluctuations or overheating. This

is also the case if the storage tank content cools down as a result

of a longer service life or of the operation of circulation systems

above the nominal temperature. In this case, only a reheating (with a

considerably smaller temperature difference) must be assured.

The PAW tank heat transfer module is equipped with a controller

which has been developed specifically for this case of operation.

The desired nominal temperature is set at the controller.

The output of the secondary pump can also be set to reduce the

transfer capacity or to adapt f. ex. to smaller boilers. Furthermore, a

circulation pump (unregulated as well as controlled by PWM signal)

can be connected with the controller. An additional relay can be

installed for a targeted stratification. Furthermore, a potential-free

relay (f. ex. as boiler demand) and a relay which switches on in parallel

with the charging function of the tank heat transfer module are

available.

250

01/2020 • Printed in Germany

PAW GmbH & Co. KG • 31789 Hameln • Germany • Phone: +49-5151-9856-0 • Fax: +49-5151-9856-98 • info@paw.eu • www.paw.eu

Maxi DN 25

T

a

n

k

h

e

a

t

t

r

a

n

s

f

e

r

m

o

d

u

l

e