System description

Leak monitoring for double-walled piping

Approval/suitability

All leak detection equipment/leak detectors in use must

comply with the basic criteria laid down for construction and

testing standards. All such preconditions which could have a

bearing on the functional and operative safety of the system

must therefore be observed.

It therefore goes without saying that the conditions for oper-

ative use have been tested by the competent authorities and

clearly defined and set down in the documents of approval

issued by them.

Double-walled piping with leak monitoring is an approved leak

detection equipment/leak detector system.

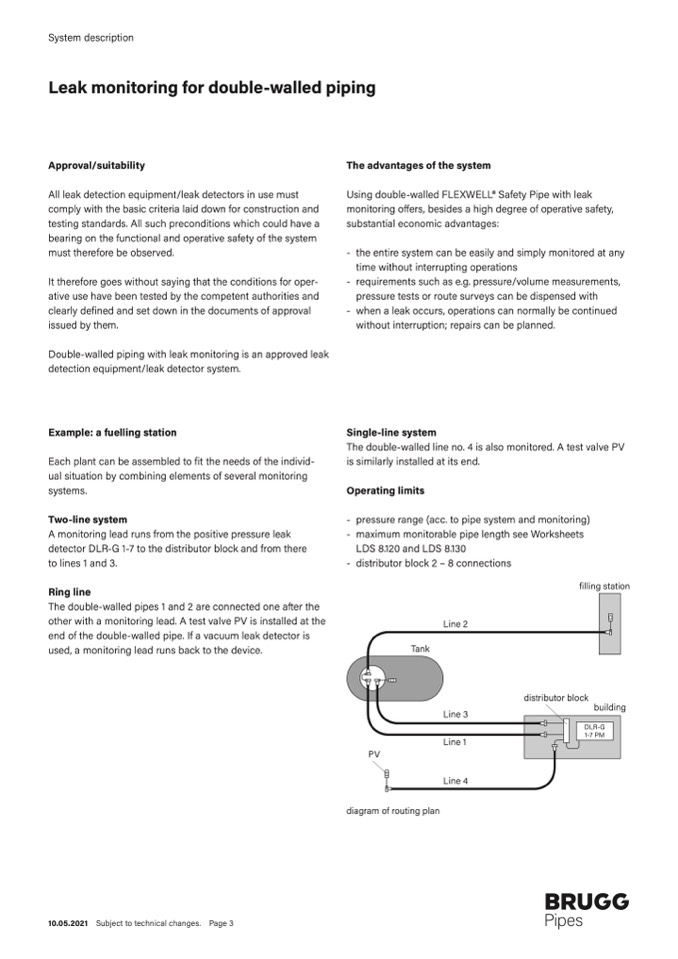

Example: a fuelling station

Each plant can be assembled to fit the needs of the individ-

ual situation by combining elements of several monitoring

systems.

Two-line system

A monitoring lead runs from the positive pressure leak

detector DLR-G 1-7 to the distributor block and from there

to lines 1 and 3.

Ring line

The double-walled pipes 1 and 2 are connected one after the

other with a monitoring lead. A test valve PV is installed at the

end of the double-walled pipe. If a vacuum leak detector is

used, a monitoring lead runs back to the device.

The advantages of the system

Using double-walled FLEXWELL® Safety Pipe with leak

monitoring offers, besides a high degree of operative safety,

substantial economic advantages:

- the entire system can be easily and simply monitored at any

time without interrupting operations

- requirements such as e.g. pressure/volume measurements,

pressure tests or route surveys can be dispensed with

- when a leak occurs, operations can normally be continued

without interruption; repairs can be planned.

Single-line system

The double-walled line no. 4 is also monitored. A test valve PV

is similarly installed at its end.

Operating limits

- pressure range (acc. to pipe system and monitoring)

- maximum monitorable pipe length see Worksheets

LDS 8.120 and LDS 8.130

- distributor block 2 – 8 connections

Line 2

Tank

Line 3

Line 1

Line 4

filling station

distributor block

building

PV

DLR-G

1-7 PM

10.05.2021

Subject to technical changes.

Page 3

diagram of routing plan