5. Panels for ceiling

and wall systems

38

Ceiling and wall radiant system – Product guide

Tel. +39 0425 75 88 11

A

Code

65 100

65 120

65 140

65 160

65 180

65 200

65 220

65 240

65 260

65 280

65 300

65 320

65 340

65 360

65 380

65 400

65 420

65 440

65 460

65 480

65 500

Support framework

C-profile spacing

mm

400

400

400

400

400

400

400

400

400

400

400

400

400

400

400

400

400

400

400

400

400

Sur.

Weight

A

m

2

kg/m

2

mm

B

H

mm mm

B

0,375

7

0,450

7

0,525

7

0,600

7

0,675

7

0,750

7

0,825

7

0,900

7

0,975

7

1,050

7

1,125

7

1,200

7

1,275

7

1,350

7

1,425

7

1,500

7

1,575

7

1,650

7

1,750

7

1,800

7

1,875

7

1000

400

35

1200

400

35

1400

400

35

1600

400

35

1800

400

35

2000

400

35

2200

400

35

2400

400

35

2600

400

35

2800

400

35

3000

400

35

3200

400

35

3400

400

35

3600

400

35

3800

400

35

4000

400

35

4200

400

35

4400

400

35

4600

400

35

4800

400

35

5000

400

35

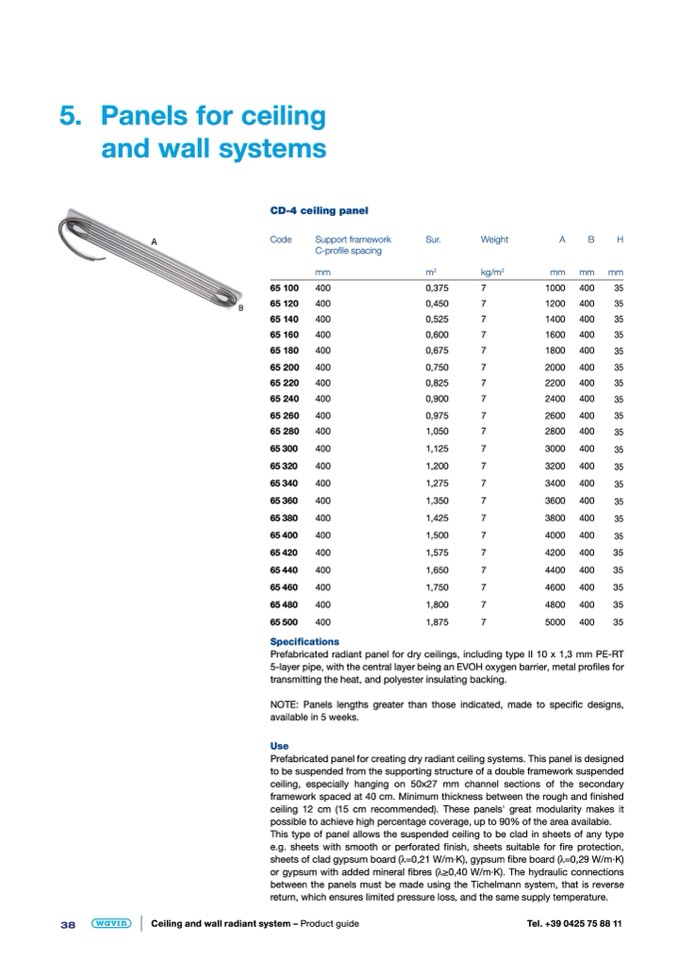

CD-4 ceiling panel

Specifications

Prefabricated radiant panel for dry ceilings, including type II 10 x 1,3 mm PE-RT

5-layer pipe, with the central layer being an EVOH oxygen barrier, metal profiles for

transmitting the heat, and polyester insulating backing.

NOTE: Panels lengths greater than those indicated, made to specific designs,

available in 5 weeks.

Use

Prefabricated panel for creating dry radiant ceiling systems. This panel is designed

to be suspended from the supporting structure of a double framework suspended

ceiling, especially hanging on 50x27 mm channel sections of the secondary

framework spaced at 40 cm. Minimum thickness between the rough and finished

ceiling 12 cm (15 cm recommended). These panels' great modularity makes it

possible to achieve high percentage coverage, up to 90% of the area available.

This type of panel allows the suspended ceiling to be clad in sheets of any type

e.g. sheets with smooth or perforated finish, sheets suitable for fire protection,

sheets of clad gypsum board (

λ

=0,21 W/m·K), gypsum fibre board (

λ

=0,29 W/m·K)

or gypsum with added mineral fibres (

λ

≥0,40 W/m·K). The hydraulic connections

between the panels must be made using the Tichelmann system, that is reverse

return, which ensures limited pressure loss, and the same supply temperature.