Product Guide

TECHNICAL FEATURES

WHITE BODY CERAMIC TILES (BIII):

White body Ceramic tiles are made with finest quality clays and with chamotte (a ceramic raw material with high percentage of silica). These raw materials are submitted

to dry grinding and suitably mixed and wet and then pressed with hydraulic presses. Quick-cycle support firing is obtained via roller kilns reaching temperatures of

approximately 1100 °C. After biscuit glazing, the vitrified product is sintered in a single-layer roller kiln at approximately 1030 °C. The resulting wall tiles have an average

bending strength that is higher than 15/ mrre in accordance with the UNI EN ISO10545-4 standard and a water absorption level that is higher than 10 %; they belong to the

Blll (GL) group according to the UNI EN 14411 standard. This class of products shows virtually no shrinkage during firing; therefore such dimensional consistency results in

extremely easy laying.

ADVICE ON LAYING

White body tiles can be laid using either tile adhesives or cement mortar. Under no circumstances should the tiles be wet before laying when using acrylic or vinyl resin based

adhesives or two- component organic solvent based adhesives. When laying large sized tiles it is best to adopt the two layer spreading method and, when the laying surface

is very large, to provide for suitable expansion joints which must not be spaced more than 4-5 linear meters apart from one another.

IMPORTANT POINTS TO REMEMBER WHILE LAYING THESE TILES

When laying on wet concrete or plaster, leave to dry for at least one week for each centimetre of thickness.

When laying on brick, never lay on tile adhesive measuring more than 4-5 mm in thickness. For laying on flexible supports (for example plasterboard panels, polymer panels,

etc.) which may result in movement of the tiles, we advise laying on tile adhesive measuring no more than 2-3 mm in thickness and to use class C2 or D1 glues.

For laying on waterproof brick, which prevents the release of damp, we advise laying on tile adhesive measuring no more than 3 mm in thickness and to use class C2 or D1

glues.

Avoid laying without expansion joints or joints where stress due to expansion is released directly onto the tile.

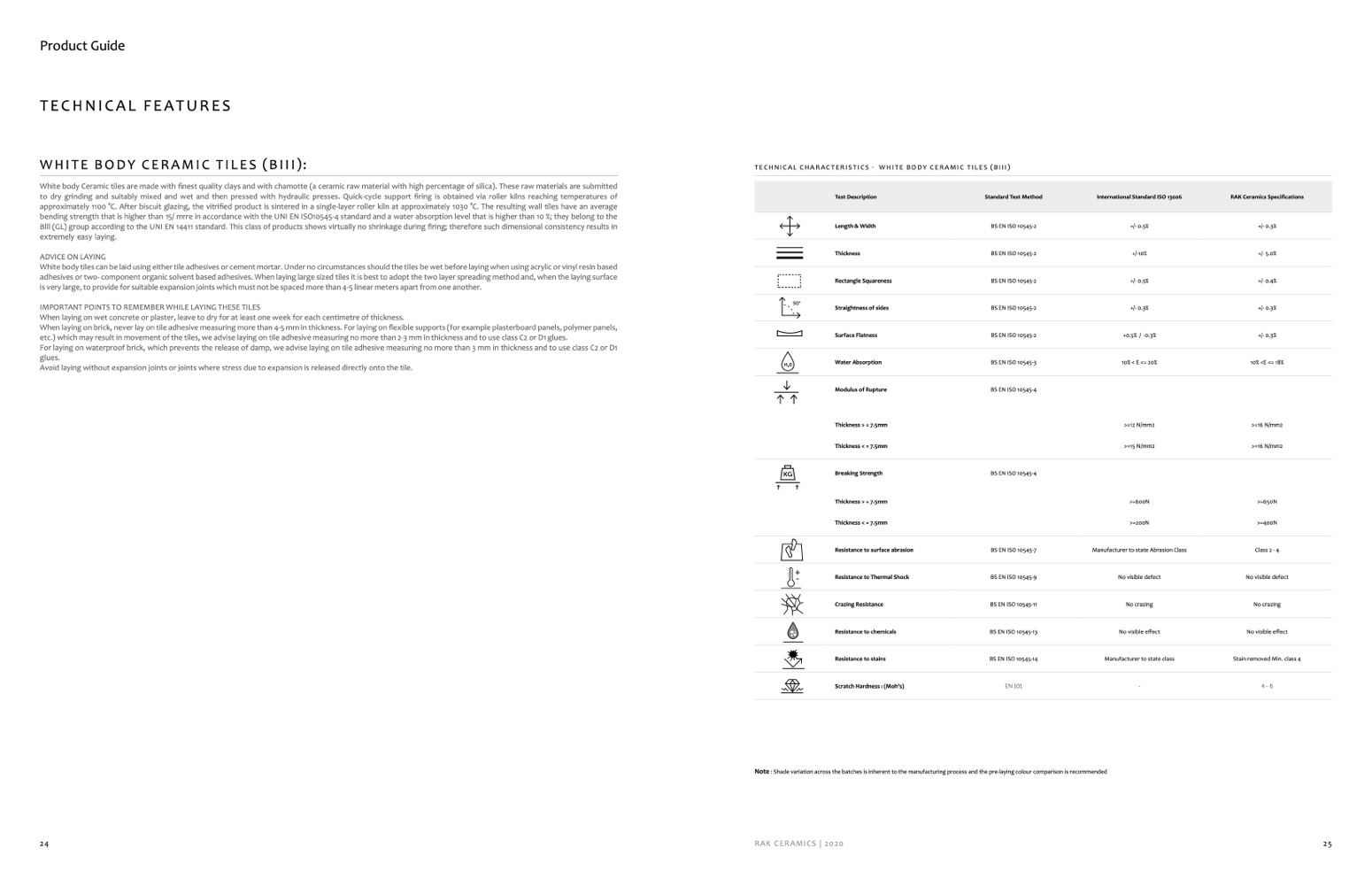

TECHNICAL CHARACTERISTICS - WHITE BODY CERAMIC TILES (BIII)

Test Description

Standard Test Method

International Standard ISO 13006

RAK Ceramics Specifications

Length & Width

Thickness

Rectangle Squareness

Straightness of sides

Surface Flatness

Water Absorption

Modulus of Rupture

Thickness > = 7.5mm

Thickness < = 7.5mm

Breaking Strength

Thickness > = 7.5mm

Thickness < = 7.5mm

Resistance to surface abrasion

Resistance to Thermal Shock

Crazing Resistance

Resistance to chemicals

Resistance to stains

Scratch Hardness : (Moh’s)

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-2

BS EN ISO 10545-3

BS EN ISO 10545-4

BS EN ISO 10545-4

BS EN ISO 10545-7

BS EN ISO 10545-9

BS EN ISO 10545-11

BS EN ISO 10545-13

BS EN ISO 10545-14

EN 101

+/- 0.5%

+/-10%

+/- 0.5%

+/- 0.3%

+0.5% / -0.3%

10% < E <= 20%

>=12 N/mm2

>=15 N/mm2

>=600N

>=200N

Manufacturer to state Abrasion Class

No visible defect

No crazing

No visible effect

Manufacturer to state class

-

+/- 0.3%

+/- 5.0%

+/- 0.4%

+/- 0.3%

+/- 0.3%

10% <E <= 18%

>=16 N/mm2

>=16 N/mm2

>=650N

>=400N

Class 2 - 4

No visible defect

No crazing

No visible effect

Stain removed Min. class 4

4 - 6

24

RAK CERAMICS | 2020

25

Note : Shade variation across the batches is inherent to the manufacturing process and the pre-laying colour comparison is recommended