IN LINE CENTRIFUGAL PUMPS

LPS

TYPE KEY AND CURVE SPECIFICATIONS

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906:2012 – Grade 3B

The curves refer to effective speed of asynchronous motors at 50 Hz, 2 poles.

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of = 1 mm

2

/s (1 cSt)

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best

efficiency point.

50Hz

Rev. P

Symbols explanation:

Q

=

H

=

P

2

=

=

MEI =

volume flow rate

total head

pump power input (shaft power)

pump efficiency

minimum efficiency index

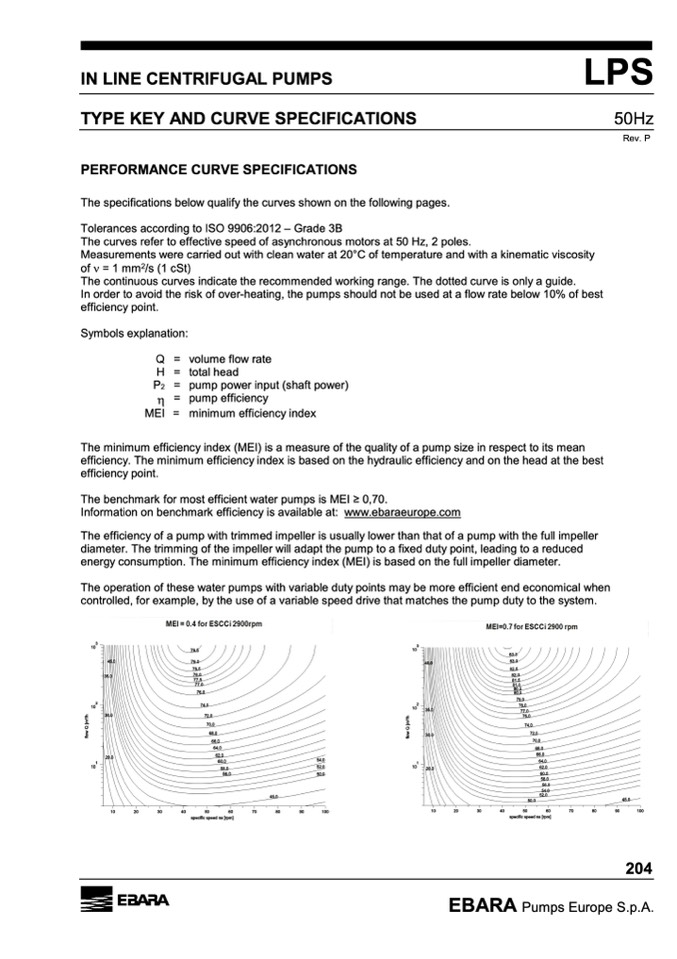

The minimum efficiency index (MEI) is a measure of the quality of a pump size in respect to its mean

efficiency. The minimum efficiency index is based on the hydraulic efficiency and on the head at the best

efficiency point.

The benchmark for most efficient water pumps is MEI ≥ 0,70.

Information on benchmark efficiency is available at: www.ebaraeurope.com

The efficiency of a pump with trimmed impeller is usually lower than that of a pump with the full impeller

diameter. The trimming of the impeller will adapt the pump to a fixed duty point, leading to a reduced

energy consumption. The minimum efficiency index (MEI) is based on the full impeller diameter.

The operation of these water pumps with variable duty points may be more efficient end economical when

controlled, for example, by the use of a variable speed drive that matches the pump duty to the system.

Präsentationstitel

17

204

EBARA Pumps Europe S.p.A.