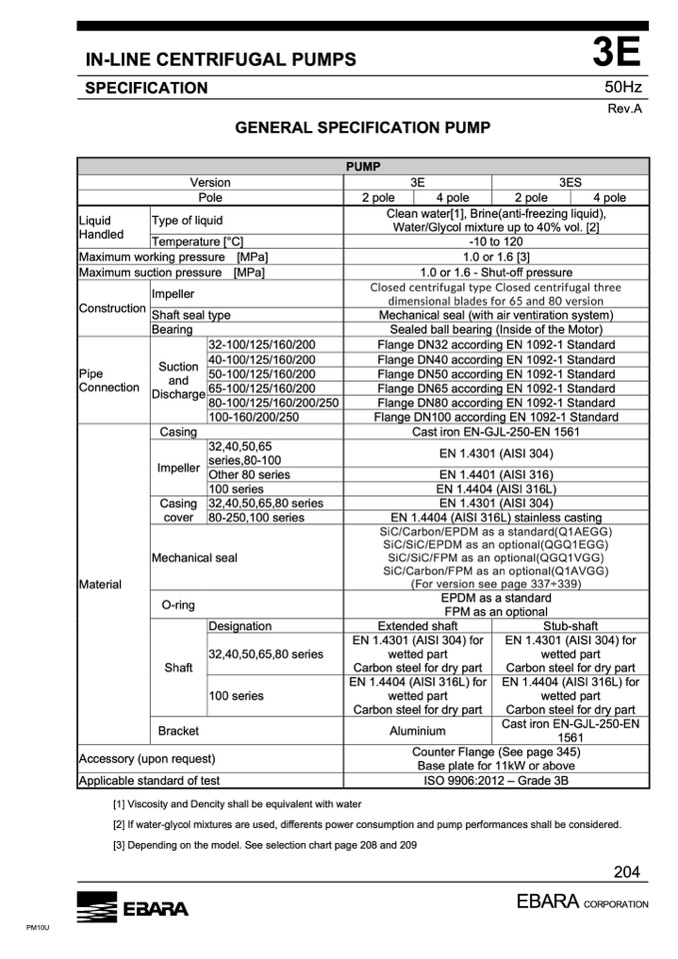

IN-LINE CENTRIFUGAL PUMPS

3E

50Hz

Rev.A

Water/Glycol mixture up to 40% vol. [2]

-10 to 120

1.0 or 1.6 [3]

1.0 or 1.6 - Shut-off pressure

Mechanical seal (with air ventiration system)

Sealed ball bearing (Inside of the Motor)

Flange DN32 according EN 1092-1 Standard

Flange DN40 according EN 1092-1 Standard

Flange DN50 according EN 1092-1 Standard

Flange DN65 according EN 1092-1 Standard

Flange DN80 according EN 1092-1 Standard

Flange DN100 according EN 1092-1 Standard

Cast iron EN-GJL-250-EN 1561

EN 1.4301 (AISI 304)

EN 1.4401 (AISI 316)

EN 1.4404 (AISI 316L)

EN 1.4301 (AISI 304)

EN 1.4404 (AISI 316L) stainless casting

EPDM as a standard

FPM as an optional

SPECIFICATION

GENERAL SPECIFICATION PUMP

PUMP

Version

Pole

Type of liquid

Temperature [°C]

3E

3ES

2 pole

Clean water[1], Brine(anti-freezing liquid),

4 pole

2 pole

4 pole

Liquid

Handled

Maximum working pressure

Maximum suction pressure

[MPa]

[MPa]

Impeller

Construction

Shaft seal

Bearing

Suction

Pipe

and

Connection

Discharge

Casing

Impeller

Casing

cover

Material

O-ring

Shaft

Bracket

type

Closed centrifugal type Closed centrifugal three

dimensional blades for 65 and 80 version

32-100/125/160/200

40-100/125/160/200

50-100/125/160/200

65-100/125/160/200

80-100/125/160/200/250

100-160/200/250

32,40,50,65

series,80-100

Other 80 series

100 series

32,40,50,65,80 series

80-250,100 series

Designation

32,40,50,65,80 series

100 series

Extended shaft

EN 1.4301 (AISI 304) for

wetted part

Carbon steel for dry part

EN 1.4404 (AISI 316L) for

wetted part

Carbon steel for dry part

Aluminium

Stub-shaft

EN 1.4301 (AISI 304) for

wetted part

Carbon steel for dry part

EN 1.4404 (AISI 316L) for

wetted part

Carbon steel for dry part

Cast iron EN-GJL-250-EN

1561

Mechanical seal

SiC/Carbon/EPDM as a standard(Q1AEGG)

SiC/SiC/EPDM as an optional(QGQ1EGG)

SiC/SiC/FPM as an optional(QGQ1VGG)

SiC/Carbon/FPM as an optional(Q1AVGG)

(For version see page 337÷339)

Accessory (upon request)

Applicable standard of test

Counter Flange (See page 345)

Base plate for 11kW or above

ISO 9906:2012 – Grade 3B

[1] Viscosity and Dencity shall be equivalent with water

[2] If water-glycol mixtures are used, differents power consumption and pump performances shall be considered.

[3] Depending on the model. See selection chart page 208 and 209

204

EBARA

CORPORATION

PM10U