RENOVA ULTRA panel

Code

10 16 64

10 16 65

10 16 66

Specifications

Material Comp.

strength

10% kPa

EPS400 400

EPS300 300

EPS300 300

Therm. Res.

A

m

2

K/W

mm

0.27

1400

0.75

1400

1.25

1400

B

H

Sur.

mm

mm

m

2

800

20

1.12

800

35

1.12

800

50

1.12

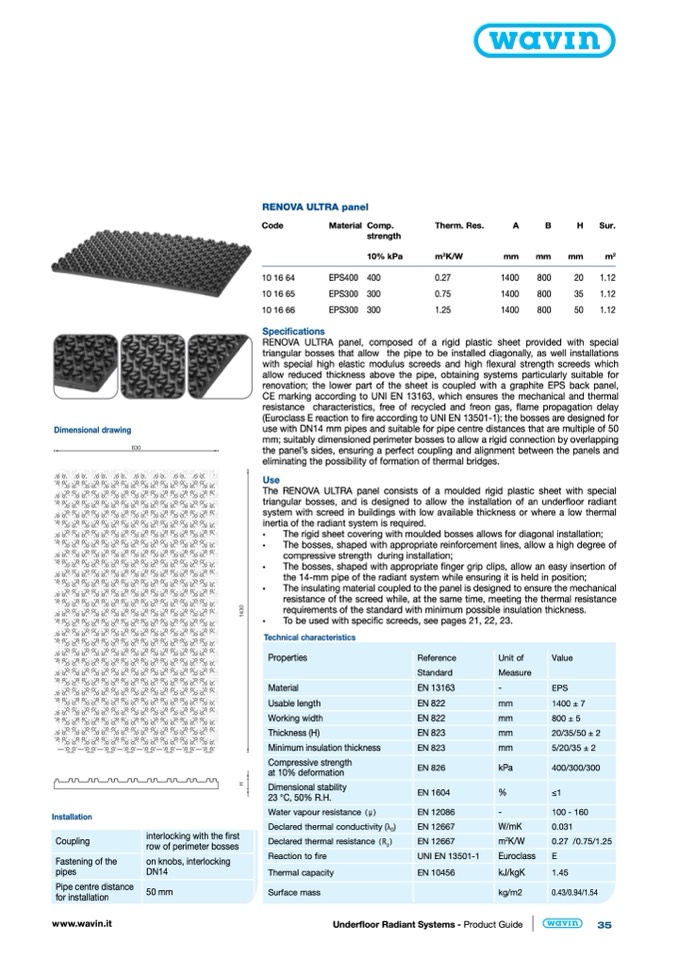

Dimensional drawing

RENOVA ULTRA panel, composed of a rigid plastic sheet provided with special

triangular bosses that allow the pipe to be installed diagonally, as well installations

with special high elastic modulus screeds and high flexural strength screeds which

allow reduced thickness above the pipe, obtaining systems particularly suitable for

renovation; the lower part of the sheet is coupled with a graphite EPS back panel,

CE marking according to UNI EN 13163, which ensures the mechanical and thermal

resistance characteristics, free of recycled and freon gas, flame propagation delay

(Euroclass E reaction to fire according to UNI EN 13501-1); the bosses are designed for

use with DN14 mm pipes and suitable for pipe centre distances that are multiple of 50

mm; suitably dimensioned perimeter bosses to allow a rigid connection by overlapping

the panel’s sides, ensuring a perfect coupling and alignment between the panels and

eliminating the possibility of formation of thermal bridges.

Use

The RENOVA ULTRA panel consists of a moulded rigid plastic sheet with special

triangular bosses, and is designed to allow the installation of an under

floor radiant

system with screed in buildings with low available thickness or where a low thermal

inertia of the radiant system is required.

•

The rigid sheet covering with moulded bosses allows for diagonal installation;

•

The bosses, shaped with appropriate reinforcement lines, allow a high degree of

compressive strength during installation;

•

The bosses, shaped with appropriate finger grip clips, allow an easy insertion of

the 14-mm pipe of the radiant system while ensuring it is held in position;

•

The insulating material coupled to the panel is designed to ensure the mechanical

resistance of the screed while, at the same time, meeting the thermal resistance

requirements of the standard with minimum possible insulation thickness.

•

To be used with specific screeds, see pages 21, 22, 23.

Installation

Coupling

Fastening of the

pipes

Pipe centre distance

for installation

interlocking with the first

row of perimeter bosses

on knobs, interlocking

DN14

50 mm

Technical characteristics

Properties

Material

Usable length

Working width

Thickness (H)

Minimum insulation thickness

Compressive strength

at 10% deformation

Dimensional stability

23 °C, 50% R.H.

Water vapour resistance (μ)

Declared thermal conductivity (λ

D

)

Declared thermal resistance (R )

D

Reaction to fire

Thermal capacity

Surface mass

Reference

Standard

EN 13163

EN 822

EN 822

EN 823

EN 823

EN 826

EN 1604

EN 12086

EN 12667

EN 12667

UNI EN 13501-1

EN 10456

Unit of

Value

Measure

-

EPS

mm

1400 ± 7

mm

800 ± 5

mm

20/35/50 ± 2

mm

5/20/35 ± 2

kPa

400/300/300

%

≤1

-

100 - 160

W/mK

0.031

m

2

K/W

0.27 /0.75/1.25

Euroclass

E

kJ/kgK

1.45

kg/m2

0.43/0.94/1.54

www.wavin.it

Underfloor Radiant Systems - Product Guide

35