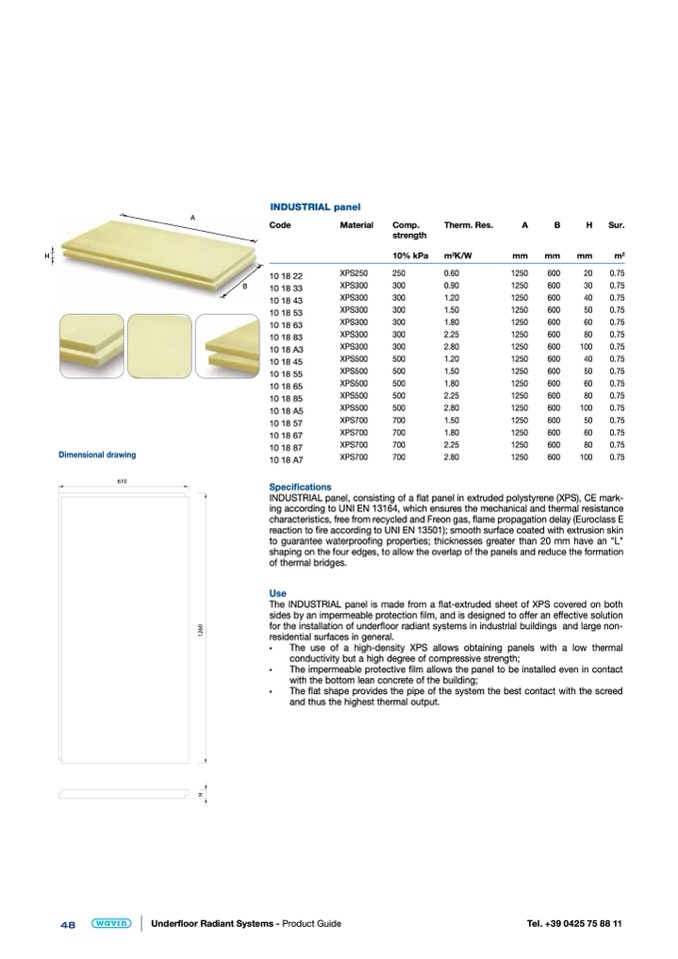

Dimensional drawing

610

10 18 22

10 18 33

10 18 43

10 18 53

10 18 63

10 18 83

10 18 A3

10 18 45

10 18 55

10 18 65

10 18 85

10 18 A5

10 18 57

10 18 67

10 18 87

10 18 A7

Specifications

XPS250

250

0.60

XPS300

300

0.90

XPS300

300

1.20

XPS300

300

1.50

XPS300

300

1.80

XPS300

300

2.25

XPS300

300

2.80

XPS500

500

1.20

XPS500

500

1.50

XPS500

500

1.80

XPS500

500

2.25

XPS500

500

2.80

XPS700

700

1.50

XPS700

700

1.80

XPS700

700

2.25

XPS700

700

2.80

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

1250

600

20

0.75

30

0.75

40

0.75

50

0.75

60

0.75

80

0.75

100

0.75

40

0.75

50

0.75

60

0.75

80

0.75

100

0.75

50

0.75

60

0.75

80

0.75

100

0.75

48

Underfloor Radiant Systems - Product Guide

Tel. +39 0425 75 88 11

INDUSTRIAL panel

Code

Material

Comp.

strength

10% kPa

Therm. Res.

A

m

2

K/W

mm

B

H

Sur.

mm

mm

m

2

INDUSTRIAL panel, consisting of a flat panel in extruded polystyrene (XPS), CE mark-

ing according to UNI EN 13164, which ensures the mechanical and thermal resistance

characteristics, free from recycled and Freon gas, flame propagation delay (Euroclass E

reaction to fire according to UNI EN 13501); smooth surface coated with extrusion skin

to guarantee waterproofing properties; thicknesses greater than 20 mm have an "L"

shaping on the four edges, to allow the overlap of the panels and reduce the formation

of thermal bridges.

Use

The INDUSTRIAL panel is made from a flat-extruded sheet of XPS covered on both

sides by an impermeable protection film, and is designed to offer an effective solution

for the installation of underfloor radiant systems in industrial buildings and large non-

residential surfaces in general.

•

The use of a high-density XPS allows obtaining panels with a low thermal

conductivity but a high degree of compressive strength;

•

The impermeable protective film allows the panel to be installed even in contact

with the bottom lean concrete of the building;

•

The flat shape provides the pipe of the system the best contact with the screed

and thus the highest thermal output.

H

1

2

6

0