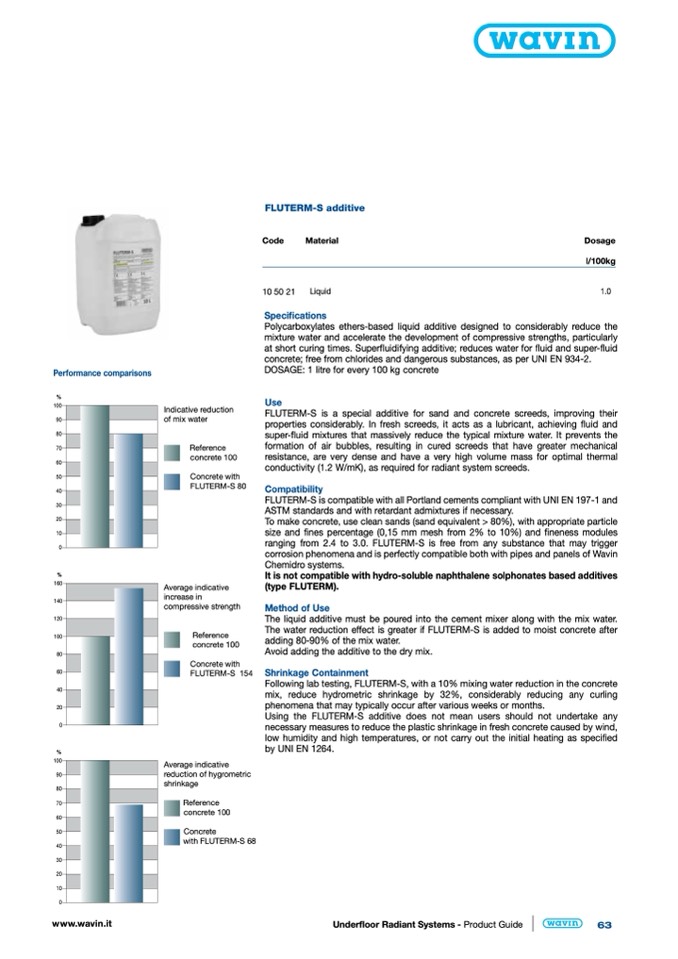

Performance comparisons

FLUTERM-S additive

Code

Material

Dosage

l/100kg

10 50 21

Liquid

1.0

Specifications

Polycarboxylates ethers-based liquid additive designed to considerably reduce the

mixture water and accelerate the development of compressive strengths, particularly

at short curing times. Superfluidifying additive; reduces water for fluid and super-fluid

concrete; free from chlorides and dangerous substances, as per UNI EN 934-2.

DOSAGE: 1 litre for every 100 kg concrete

100

%

90

100

160

100

90

80

70

60

50

40

30

20

10

90

80

%

%

%

%

100

90

80

70

60

50

40

30

20

10

0

%

160

140

120

100

80

60

40

20

0

%

100

90

80

%

%

100

90

Use

%

%

140

Indicative reduct1i0o0n

80

160

160

FLUTERM-S is a special additive for sand and concrete screeds, improving their

ofmix9w0ater

120

80

70R

90

80

70properties c1o40nsiderably. In fresh screeds, it acts as a lubricant, achieving fluid and

140

eference

concrete 100

formation of air bubb12l0es, resulting in cured screeds that have greater mechanical

50

80

70

resistance, a

10

r

0

e very dense and have a very high volume mass for optimal thermal

100

super-fluid mixtures that massively reduce the typical mixture water. It prevents the

60

120

100

60

60

40conductivity (1.2 W/mK), as req

60

uired for radiant system screeds.

50Concrete with

FLUTERM-S 80

40

40

20

size and fines percen

2

t

0

age (0,15 mm mesh from 2% to 10%) and fineness modules

80

5

0

30

80

Compatibility

20

60

FLUTERM-S is compatible with all Portland cements compliant with UNI EN 197-1 and

30

20

10

40

30

20

10

140

80

60

The liquid additive must be p

1

o

00

ured into the cement mixer along with the mix water.

60

20

10ASTM standa

40

rds and with retardant admixtures if necessary.

40

0

To make concrete, use clean sa0nds (sand equivalent > 80%), with appropriate particle

ranging from

0

2.4 to 3.0. FLUTERM-S is free from any substance that may trigger

0

0

0

0

corrosion phenomena and is perfectly compatible both with pipes and panels of Wavin

%

Chemidro systems.

%

%

100

90

100

160

It is not compatible with hydro-soluble naphthalene solphonates based additives

%

100

70

60

50

40

30

20

10

0

%

Average indicative%

increase in

100

compressive strength

Reference

90(type FLUTERM).

%

80

160

90

70

Method of Use

140

The water reduction effect is greater if FLUTERM-S is added to moist concrete after

adding 80-90% of the mix water.

70

50

120

80

concrete 100

60

40

Avoid adding the additive to the dry mix.

Concrete with

60

Shrinkage Containment

40

5

0

30

80

FLUTERM-S 154

100

40

30

20Following lab testing, F

60

LUTERM-S, with a 10% mixing water reduction in the concrete

20

10mix, reduce hydrometric shrinkage by 32%, considerably reducing any curling

40

100

90

80

70

60

50

40

30

20

10

80

70

60

50

40

30

20

10

0

80

70

60

50

40

30

20

10

0

80

70

60

50

40

30

20

10

phenomena that may typically occur after various weeks or months.

Using the FLUTERM-S additive does not mean users should not undertake any

%necessary measures to reduce%the plastic shrinkage in fresh concrete caused by wind,

100

160

2

0

0

0

%

100

90

10

0

%

20

low humidity and high0 temperatures, or not carry out the initial heating as specified

%

90

by UNI EN 1264.

%

80

160

140

160

Average indicativ10e0

reduction of hygrometric

140

90

shrinkage

70

60

60

c10o0ncrete 100

60

40

140

120

100

80

7

0

erence

7

0

50

50

C8o0ncrete

50

30

80

40

30

20

10

with FLUTERM-S 68

0

120

Ref

40

20

30

10

20

0

10

60

40

20

120

120

100

80

60

40

60

40

20

20

0

0

0

0

0

0

www.wavin.it

Underfloor Radiant Systems - Product Guide

63